|

So

I let

that one go, but having convinced myself I could have an

M in the

garage I resolved to find one closer to home. A

short

while later I was

looking at a picture on ytmag.com of this 1950 M about 25 miles

away from

me, and somewhere I'm

sure a soprano started warming up to sing. It took a week or

two

to arrange to get over to see it, but I remembered to bring my

checkbook with me. This one doesn't have the pristine

originality

of the one I'd seen on eBay but it's a smooth-running

easy-starting old girl, and

it was close, and that was enough.

Once in a while I

drive it down to the corner gas station to

put

air in the front tires, or just take it for a spin and enjoy the sound

of the engine and the waves of the neighbors. Some year I

still hope to

get back out in the country where I can put the M to work.

In the meantime, seeing this handsome machine in my garage

warms my heart every day. And it's hard to beat

the

satisfaction of fixing up an honorable veteran like this. I'm

not out

for show-quality restoration but I want the

tractor to look decent and

be solid mechanically, and I've already enjoyed many

hours slowly

tinkering and learning. |

| |

The electrical system

was one of the first tasks: All the ignition and lighting

circuit wiring was

pretty much shot and the charging system didn't work.

Replacing the wiring

sounded simple enough when I got started, but I eventually figured out

that just putting new wires where the old ones had been wasn't going to

cut it. I couldn't match the existing wiring up to the

diagrams in the parts book, and there was no existing wiring at all

connected to the

generator. The electrical system

was one of the first tasks: All the ignition and lighting

circuit wiring was

pretty much shot and the charging system didn't work.

Replacing the wiring

sounded simple enough when I got started, but I eventually figured out

that just putting new wires where the old ones had been wasn't going to

cut it. I couldn't match the existing wiring up to the

diagrams in the parts book, and there was no existing wiring at all

connected to the

generator.

The generator had a voltage regulator mounted on top of it, but

the tractor had evidently started life with a cutout relay instead.

A cutout relay lets current flow from the generator to

the battery but prevents it from going the other way, so you can charge

the battery up but it won't just drain back down through the generator.

The tractor operator controls the charging rate with the

light switch, which has four positions: High, Low, Dim, and

Bright.

If the lights are on (Dim or Bright), the generator charges

the battery at the high

rate. If the lights are off, the generator charges at either

the high or low rate depending on the switch position. Too

little

charging and the battery will run down; too much and the battery can be

damaged. An automatic voltage regulator has the same

basic job as the cutout relay, letting current

flow from the battery to the generator but not the other way around,

but it also solves the under- or over-charging problem. It

lets current flow from the generator to the battery whenever the battery

voltage is lower than it ought to be, but then stops as soon

as the battery is charged back up.

With a regulator there's no need for the operator to manually control

the charging rate, so the wiring

between the switch and the regulator is a little different than it

would be for a cutout relay. And there's

no need for the High and Low positions on the light switch.

(On tractors that came equipped from the factory with a

voltage regulator, the switch was truly just a light switch, and had

only three positions: Off, Dim, and Bright). My

tractor still had the four-position switch.

Not really understanding all this at the time, I ran new wires to the

regulator and hooked them up the way you should for a tractor with a

regulator, and then hooked up the other ends of the wires to the switch

the way you should for a tractor with a cutout relay. That

had the unfortunate effect of creating a direct short to ground, which

made some wires get really hot and made me re-think just how smart a

mechanic I was. With the generous help

of several folks on the ATIS

e-mail lists, and with

Robert

Melville's Farmall wiring diagrams,

I disconnected the High/Low part of the light switch and wired the rest

of it as if it were a three-position switch, and all was well.

|

|

|

|

|

|

Posing in the back

yard on a nice October afternoon, after a trip up to

Anderson

Tractor Supply

in Bluffton, Ohio to buy a set of fenders and the belt pulley.

I'd gone to Anderson's about ten years earlier to look

for fenders for the

Super M

I used to have, and had good memories of wandering around their salvage

yard. I'd found that first set on what was left of a

Farmall 400. The ones I found for this tractor were

on a

560, although they're just normal H and M fenders. Anderson's

had

another set with much nicer paint, but I didn't want the fenders to be

the nicest-looking part on the tractor--weathered but straight suits me

just fine. |

Saturday

afternoon, time to work on the tractor for a while. I put on

an

M&W aftermarket throttle lever because that's what had

been on

my old Super M,

and I like to stay with things that work. The

steering wheel made my hands all black and sooty every time I touched

it, so I painted it with clear spray-on lacquer. Looks fine

and

worked like a charm. |

|

|

|

| |

|

|

| |

|

One day while trying to start the tractor I noticed a puff of smoke

from down by the starter switch. When I tried again one of

the

mounting bolts on the side of the switch glowed red-hot.

Those are rarely good signs. So I pulled the battery

out and

took all the cables off and removed the switch, and carefully opened it

up. The cardstock insulation around one of the terminal posts

had

worn through, letting the post touch the metal switch housing and

thereby creating a direct short to ground when I pressed the contact

button. I had some polystyrene sheet left over from some

model-making, and it looked

about the same thickness as the worn-out cardstock, so with an X-Acto

knife and a hand drill and some plastic cement I made a new

insulator. Put the switch back together, put it back on the

tractor, and it starts like a champ again. Have to love these

forgiving old machines. |

|

|

|

|

|

|

|

I knew when I bought

the tractor that the power

take-off didn't work: The shaft rotated freely but I couldn't

engage

it--the PTO lever would barely move. I removed the control

rod and the

PTO guard and cleaned up the outside of the PTO housing so I could

see it better, but (not knowing what to look for) I didn't see anything

wrong. Removing the PTO meant draining the transmission oil

first, which of course was a project in itself: The

operator's

manual says to put 13 gallons of oil in the transmission, but I drained

about 18. First few gallons were kind of brown and frothy, so

some water seems to have gotten in at some point. The rest

didn't

look as bad as I'd expected, although there was a bunch of goopy sludge

left in there

that I had to clean out through the rear opening while I had the PTO

housing off. Aside from that bit of sludge at the bottom,

everything in the transmission case looks great.

|

Removing the PTO was

easy,

just a matter of removing the bolts and pulling the whole

assembly out.

All five

of the bolts

turned out to be different, so I made some notes

to help me remember how to put it back together later.

|

|

|

Looking

into the PTO housing, I could see that the shifter linkage did in fact

move,

but not far enough: Pulling up on the external shifter lever

rotated

the internal shifter arm, but not all the way to the "engaged"

position, so the sliding PTO tube didn't go far enough forward to

engage the transmission countershaft. The external

shifter

lever only

had a range of motion of about 15 degrees, and about five of those

degrees were free play (didn't move the shifter arm at all).

I

decided those five degrees of slop meant there had to be a lot of wear

on the shaft between the external shifter lever and the internal

shifter arm, wasting a lot of its range of motion. |

|

I wasn't sure I had

the skill to fix worn-out steel components, so I made another

trip to Anderson's

and picked up a replacement PTO assembly. This photo shows

the

difference: With the external shifter lever all the way up,

the

internal shifter arm is all the way forward in the "engaged" position,

so the little spring-loaded bullet-shaped poppet coming in from the

right side has snapped into the rear detent on the shifter arm.

In the photo above, of the original PTO assembly, the shifter

arm

isn't far enough forward for the rear detent to have reached the poppet. |

|

The

end of the PTO shaft on the replacement assembly is in pretty good

condition and the bearing looks fine. I had the local Case/IH

dealer replace the oil seals

on general principle... the original PTO had leaked a little bit of oil

there, which turns into a big mess surprisingly quickly. I

don't

know if this one would have leaked or not, but replacing the seals and

gasket while I had it out of the tractor seemed like pretty

easy insurance. |

|

Meanwhile, I wanted to see if I could get the

shifter linkage out of the original assembly, to at

least look at the parts which were worn out and to see

what might still be worthwhile to take to a swapmeet.

There's only one bolt that needs to be removed in order

to get the shifter parts out of there, but removing that

bolt took some trial and error--it's a bit too long to

come out without bumping into the underside of the cam

on the shifter arm, and the collar on the sliding PTO

tube is in the way. I eventually got it out by randomly

wiggling and pulling and shaking. (Getting it back

together later tested my patience and vocabularly, but I

felt like the king of the world when it finally dropped

back into place).

With the

linkage parts out where I could see them, there was very

little visible wear. The shifter arm is fastened to

the

shifter lever shaft by the above-mentioned bolt. The bolt

itself

wasn't worn out of shape, and the hole in the shaft through

which

the bolt passes wasn't distorted into an oval. It

all fit

together fairly snugly with only a little bit of slop

(the

five degrees or so of wiggle that I'd noticed earlier), and given the

size of the bolt and the diameter of the hole it didn't seem as if

anything could

have

been much different when it was new. So I checked

the

shifter lever on the other PTO assembly, and sure enough it

has four degrees of free play. So why didn't the

original one work?

After

scratching my head for a while, I finally noticed the obvious

problem: The shifter lever had been broken and re-welded to

the

shaft at some point, but at the wrong angle. In the picture

on

the right, above, you can see the weld and the angle at which the

shifter arm is leaning to the right. With the shifter lever

horizontal, that arm ought to be vertical. Since the arm is

leaning back, it can't come far enough forward to mesh the sliding PTO

tube with the transmission countershaft before the shifter lever hits

the stop. |

|

|

This

picture of the replacement PTO assembly in front

of the

original one shows the problem. Both are in the "disengaged"

position, with the shifter levers down as far as they will go.

The lever in front can rotate almost 30 degrees

counter-clockwise before it hits the stop, but the one in back is

already halfway "up" so it only has half that range of motion left.

I

put the replacement PTO on my tractor, but still need to figure out

what to do with the old one. Cutting a little notch in

the shifter lever, so it can rotate farther before it hits the stop,

seems like it'd work but it'd be kind of a hack job. Better

to

really fix the angle at which the lever is welded to the shaft, but

that's beyond my skill and equipment. Might put a tag on it

explaining what's wrong and bring it to the

swapmeet at

Portland... |

|

|

I used an old putty

knife to slowly scrape the old gasket off the

mounting flange on the rear of the transmission case, then sprayed on

some gasket sealant. The inside face of the PTO housing got

some

also, and both sides of the new gasket, then it was time to

put it

all back together. That PTO assembly feels pretty heavy when

95%

of the shaft is wobbling around inside the tractor and all you have to

hold onto is the housing and outside end of the shaft, but it's great

when it fits into place. With everything reassembled and the

transmission case refilled with oil, I gave the PTO a test run in the

garage and it all looks good. I'll watch to see if it leaks

over

time, but for now I think this job is finished. |

|

|

| |

|

|

| |

|

Next

job after getting the PTO back together was to clean the brakes up,

both of which were pretty gunked up with oil which had leaked past the

seals. Getting them apart was straightforward

except

for actually removing the old oil seals--I had to buy a gear puller

(which seemed like a good tool to have anyway). I used some

wood

blocks and a piece of old angle iron for the puller to push against,

since it didn't seem right to let it push hard against the brake shaft

itself. And hard is the right word--the puller bent the heck

out

of that piece of angle iron, but eventually the seals came out.

I bought new seals

from Case/IH ($17.70 each, plus

$2.50 for the little cork washers that go behind the big

bolt that

holds the brake drum onto the shaft), and carefully tapped them in

place with a hammer and block of wood. I cleaned everything

else

up using rags and a little gasoline, and a propane torch to boil some

remaining gunk out of the brake bands. Put it all back

together,

adjusted the brake linkages the way the operator's manual said to, and

they work a lot better now than before. Plus there are two

fewer

sources of oil drips on my garage floor. |

|

|

| |

|

Repacking grease

in the front wheel bearings turned into a big job, like they all seem

to do. First task was to build a

stand for the front end, and

fortunately I had some salvaged 4x4s and plywood on hand.

Once I

had the wheels apart and the axles cleaned up so I could compare them

to the parts book, I realized that neither wheel had the grease

retaining seals that

are supposed to go up next to the bearings. And the castle

nut on the

right side had the threads all worn down somehow so it wouldn't tighten

up

(beats me how the threads on the inside of a nut get worn down).

But those things are all still available from the CaseIH

parts counter, so after another $46 I was ready to go. |

|

|

| |

|

|

I

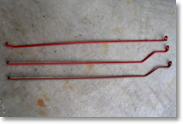

bought this shiny red pair of hydraulic control rods because

I needed the one with the bends in it, which controls the

valve for the remote cylinder. The straight one controls

the Lift-All pump, but I already had one of those on the

tractor and a second one that I'd bought sight unseen

because I mistakenly thought it was the other type. I

didn't want yet another straight rod, but the bent ones are

hard to come by. I

bought this shiny red pair of hydraulic control rods because

I needed the one with the bends in it, which controls the

valve for the remote cylinder. The straight one controls

the Lift-All pump, but I already had one of those on the

tractor and a second one that I'd bought sight unseen

because I mistakenly thought it was the other type. I

didn't want yet another straight rod, but the bent ones are

hard to come by.

When I had them side by side, I could see that the rods

themselves were the same length. Since I had a spare

straight rod, I cut off the little stop peg and bent the rod

to match the other one. It's not 100% identical to the

genuine rod, but it's mighty close--that's it in the

pictures, after I painted it with primer. It was fun making

what I thought was a useless extra rod into the part I

needed, and afterwards I re-sold those shiny red ones. |

|

|

Same deal with the support bracket for the remote valve rod.

I bought this arm to get the extra little bracket that

clamps onto the end, but once I looked at it I figured I

could make one to do the job well enough. I had some sheet

metal left over from working on the grille (below) and cut

it and bent it to be a reasonable approximation of the

original, put it on my tractor, then sold the other arm and

bracket. Didn't quite get all my money back, but it was

pretty close. |

|

|

|

| |

|

|

|

|

|

| |

August

2006 |

June 2007 |

October

2007 |

November

2008 |

January 2009 |

|

|

| |

|

|

|

I

hadn't intended to ever sell the M, but one day I

noticed a photo ad for another tractor... a late 1953

Super M, very much like

the one I'd

owned a dozen years ago only even nicer, and as soon

as I saw the ad I knew I was done for. Just like

that one I'd had before, this new Super M has the

transitional grille, sort of halfway between the regular

M/Super M grille and the Super MTA grille. Those

grilles apparently only showed up on the very late

production Super Ms, as tooling was gearing up for the

Super MTAs. I've often wished I'd hung onto that

other Super M and had never seen another just like it in

the dozen years since I let it go... so when this one

came along I didn't lose any sleep over buying it.

For a brief and enjoyable period of time I had two

tractors here in the suburbs, but I reluctantly sold the

M to make room in the garage and my checkbook for the

new Super M. Now this one, I

definitely plan to hang onto for the long haul. |

|

|

|